Isolators for Pharmaceutical & Medical

Gloveboxes Group provides Custom-designed isolators and solutions for the changing needs of the pharmaceutical industry. The Group has extensive long experience in the most varied pharmaceutical sectors, whether for sterile or toxic applications.

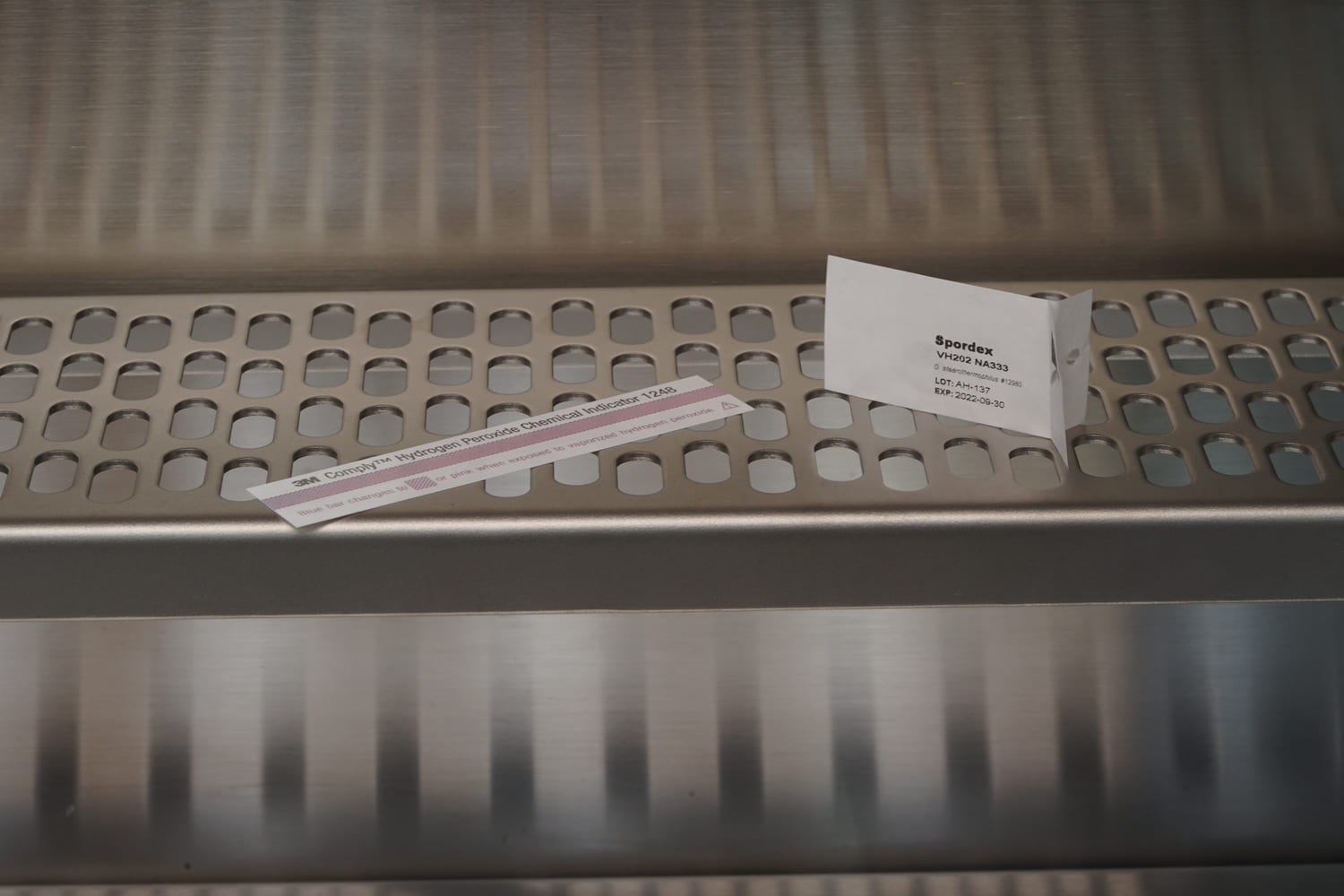

Sterile isolators enable weighing, formulation, sterility testing, filling, etc… and any kind of processes requiring germ free conditions. Toxic isolators ensure weighing, formulation, conditioning and any other handling of potential harmful active ingredients which need a strong safety for the operator and the environment.

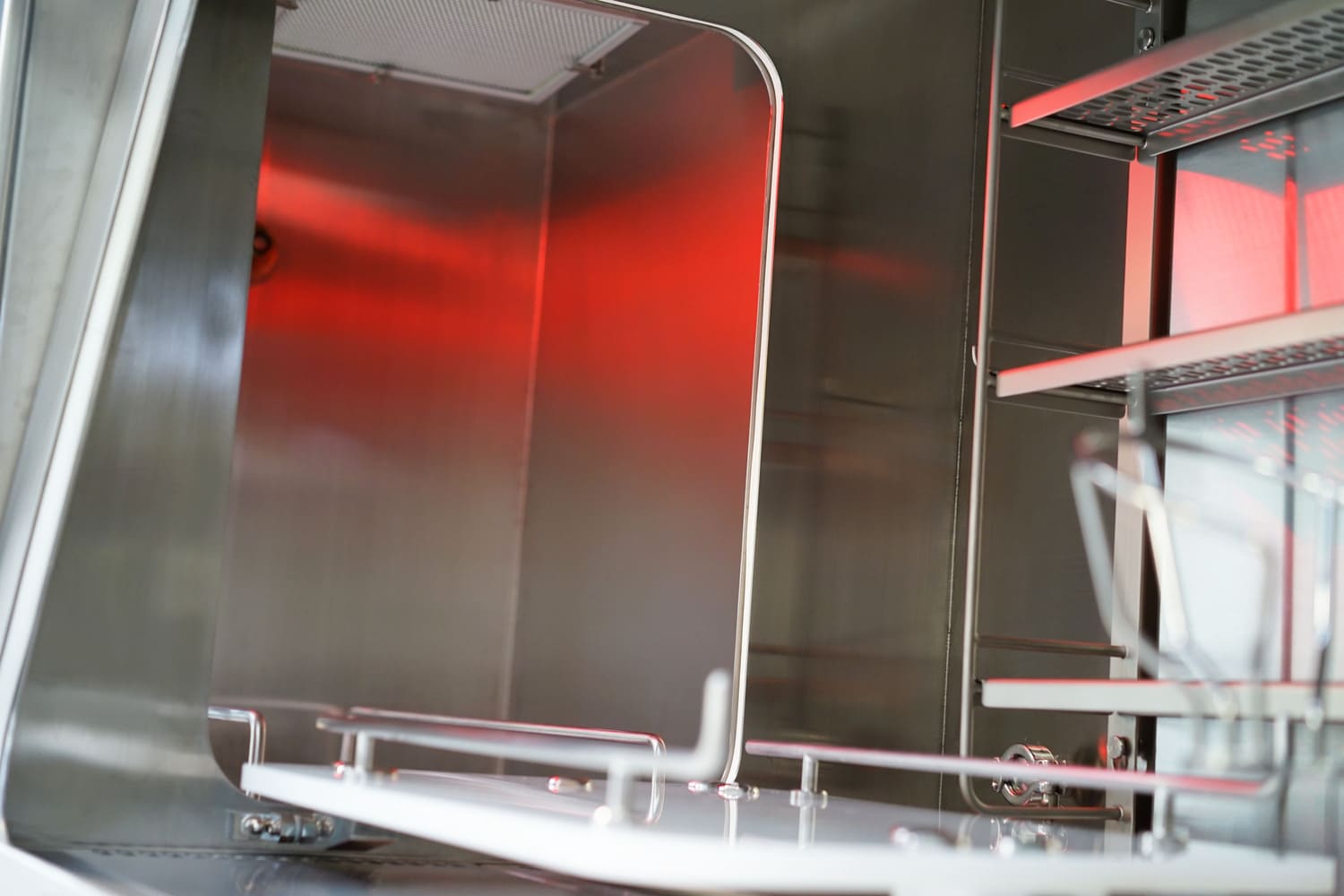

Most of our custom-designed isolators operate safely through strong procedures, precise manufacturing and experienced proceeding. The tightness of our isolators matches with high requirements of ISO 10648-2 standards, i.e. class 1 or 2 generally. We provide isolators and systems with turbulent flow or laminar flow and the operating mode can be either positive, or negative or a mix of both.

We offer high flexibility with our customer’s constraints and deliver turnkey solutions with integrated equipment such as bio-decontamination, rapid transfer ports, filling and stoppering machines, gloves integrity testers…

To protect APIs and operators, we design bespoke Restriced Access Barrier Systems (RABS) which can be open or closed, offer traceability of any access and enable upgrade protection of existing lines to fulfill annex 1 recommendations.

In our wide range of specific products, we design also on request custom-designed laminar-flow biosafety cabinets class II, weighing, sampling and collection booths as well as tailored transfer trolleys fitted as standalone stations with autonomous laminar flow and temperature cooling, thus enabling transfer of sensitive products in a safe and regulated way.

Our isolators are ideal for nanoparticle cancer drugs, microbiome science and surgical implants due to the enclosed design that eliminates product cross-contamination. Additionally, with tailor-made designs, enhanced flexibility of use and ergonomics, modeling and layout capabilities – these isolators provide an efficient solution for powder process operations. With an emphasis on turbulent flow and laminar flow designs, these systems provide the ideal environment for critical processes.

By leveraging advanced automation technologies, isolator solutions can be optimized to ensure maximum efficiency and efficacy of product protection schemes. Moreover, with comprehensive in-house engineering capabilities, these solutions are designed to optimize energy requirements while maintaining stringent safety standards.

API and HPAPI powder process isolators provide a reliable and cost-effective solution to ensure product protection and cleanroom operations – regardless of the application at hand.

INERT CORP

One Industrial Way

Amesbury, MA USA 01913

Phone: (978) 462 4415

Fax: (978) 462 3338

Email: sales@inertcorp.com

GLOVEBOXES INC

One Industrial Way

Amesbury, MA USA 01913

Phone: (978) 462 4415

Fax: (978) 462 3338

Email: contact@gloveboxes.com

JACOMEX SAS

184 rue du bicentenaire

01120 Dagneux – France

Phone: +33 472 251 900

Fax: +33 472 251 901

Email: contact@jacomex.com

EREA SAS

Route de Barleux

80200 Peronne – France

Phone: +33 (0)3 22 84 39 99

Fax: +33 (0)3 22 84 40 60

Email: info@erea.com